- Sheetcam z problem full crack#

- Sheetcam z problem manual#

- Sheetcam z problem full#

- Sheetcam z problem license#

- Sheetcam z problem professional#

To prevent rounding at the outer corners of the cut trajectory, it is possible to bypass these corners. SheetCam automatically finds holes and windows in the work area of the workpiece, assigns the optimal cutting direction and the length of the tool input and output path. This reduces the contamination of the nozzles (and, accordingly, improves the quality of the cut) and prolongs their service life. Instead of plunging directly into the workpiece, the torch torch can “crawl” along an inclined (remaining, of course, vertical), thereby reducing the amount of material thrown back into the torch. The possibility of an inclined entrance to the material is realized. Automatic determination of the cutting order ensures that internal contours will be cut earlier than external ones. In SheetCam processing settings the width of the slot is adjusted, the time for heating with oxygen-cutting is set, the delay for burning is set. This, for example, is widely used on machines controlled by the Mach3 program.

Sheetcam z problem full#

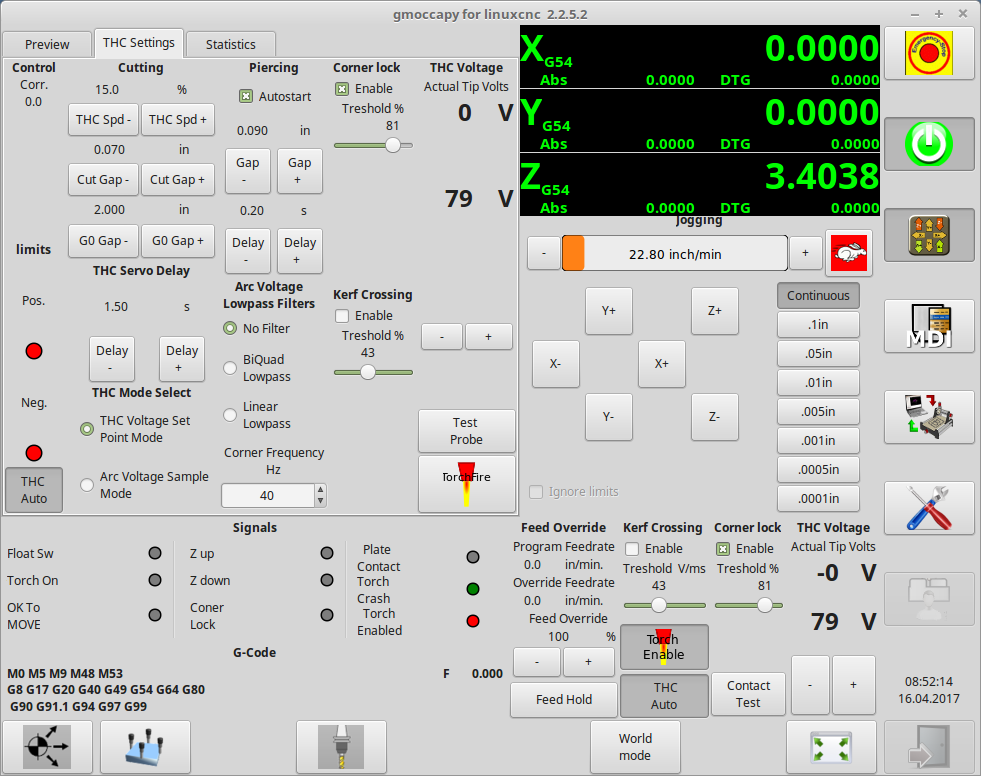

For machines with full Z-axis control, users can program such jet cutting options as the burn height and cutting depth. Plasma, laser, hydroabrasive and gas-oxygen cutting.

Unlike most CAM packages, the format of the SheetCam postprocessors is open and documented. Also, SheetCam allows users to edit and create their own postprocessors. These are small programs that are run at the stage of generating the output file and create codes for a specific machine control system. To cope with this problem in SheetCam and used by postprocessors. Although G-codes, in general, are standardized, some machines “speak” in different dialects of the G-code language. A large number of postprocessors offered by the program extend the range of application of control programs created in SheetCam, on various machine tools.

Sheetcam z problem professional#

At a sufficiently low cost, the program completely absorbed all the necessary set of functions necessary for high-quality and professional programming of machining on CNC machines. Also the program perfectly copes with the basic CAM tasks of milling, engraving, batch drilling, laser, waterjet and gas-oxygen cutting.

Sheetcam z problem license#

Programming with sheetCAM 5.1.12 full license foreverĭescription: SheetCam – One of the best available CAM-packages for preparing G-codes for plasma cutting machines with numerical program control.

Sheetcam z problem full crack#

Sheetcam z problem manual#

G128 corresponds to DGN 128, but i don't know what's Y049.1 and what it corresponds to,it might be a switch that is not active i'm not sure i'm still looking in some hardware and installation manual i found online. I looked for what triggering this signal in the ladder diagram and found this (please check the attached picture) I did my research and found out that there is a z axis interlock signal, it was shown in the diagnostic parameter DGN 128: 00000011 and the parameter PRM008#7 is 1 so the interlock is only effective on the Z axis. i was able to get rid of these errors by manually moving everything back to its original place.īut the problem was that i couldn't move the Z axis in JOG mode nor in AUTO, i can only move it with the HANDLE. I got a 3 axis milling machine with a Fanuc OM controller, its been running for years without using the ATC, until i accidentally ran a G-code ordering to change tools(T2M6) resulting in a few errors that appeared concerning the position of the ATC arm and the counter of the tool pot.

0 kommentar(er)

0 kommentar(er)